What is Geofoam ?

¡ Geofoam is expanded polystyrene (EPS) or extruded polystyrene (XPS) manufactured into large lightweight blocks.

¡ The primary function of geofoam is to provide a lightweight void fill below a highway, bridge approach, embankment or parking lot.

¡ EPS Geofoam minimizes settlement on underground utilities.

¡ EPS Geofoam is used widely as compared to XPS Geofoam.

¡ Since the manufacturing of XPS causes emissions of CFCs and HFCs harmful to the nature.

Geofoam Blocks

¡ The blocks vary in size but are often 2 m x 0.75 m x 0.75 m.

APPLICATIONS

¡ SLOPE

STABILIZATION:

To

reduce the tendency of failure of portion of the soil, the crest of the slope

is excavated and replaced by the super lightweight material EPS geofoam.

¡ Alternative

solutions:

•

Changing of the slope inclination,

•

Buttressing the toe of the embankment using

soil nailing

•

Any other solution that may affect the

geometry of the slope or the surrounding land or may not be feasible for many

reasons.

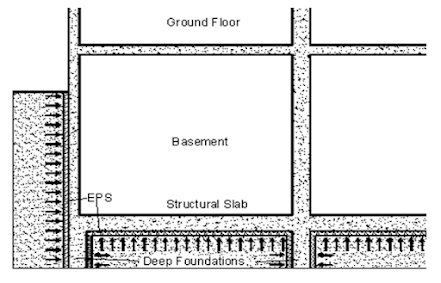

¡ REDUCING

LATERAL PRESSURE ON RETAINING STRUCTURES

•

To reduce:

ü

static earth pressure acting behind an

abutment during and after construction of the backfill

ü

the dynamic earth pressure due to

earth-quakes and traffic loads after the construction

•

Finite element analysis, showed 85% reduction

in the overall bending moment when utilizing 12kg/m3 EPS geofoam.

•

The 20kg/m3 geofoam showed 70% reduction

compared with the case of no geofoam.

COMPRESSIBLE INCLUSION

AGAINST EXPANSIVE SOIL

¡ Expansive

soils or swelling soils are those soils that have the tendency to increase in

volume when water is available and to decrease in volume if water is removed.

¡ Upon

soil heave EPS geofoam compresses according to its own stress strain relation.

¡ The

geofoam will also act as a form for the slab.

¡ EMBANKMENT

FILL TO REDUCE SETTLEMENT

•

Figure shows a situation of constructing a

new embankment on soft ground.

•

Large settlement can be experienced under the

load of the conventional embankment fill.

Existing utility line: damaged if not designed for large deflections.

¡ WIDENING EMBANKMENTS

•

The self-standing property will reduce the

additional space without the need of a retaining wall.

¡ STRESS

REDUCTION IN BURIED PIPES

•

The compressible inclusion of EPS geofoam may

be utilized to reduce loading above rigid conduits.

•

Thin layers of EPS geofoam are placed some

0.5m above the rigid conduit.

¡ PAVEMENT

AND RAILWAY INSULATION

•

The cycle of winter freezing and spring

thawing of soil can affect transportation facilities such as roads and

railroads.

•

This is because the ground surface heaves as

a result of freezing and settles upon thawing.

Geofoam for roadway

embankments as an alternative to ground improvement

¡ Maintenance

is not required.

¡ All

weather resistant.

¡ The

overall time for construction is typically much shorter and less.

¡ Saving

cost of heavy equipments.

¡ In

consideration of these benefits, the typically higher unit cost of geofoam is

usually more than offset by savings when overall project costs are

considered.

ADVANTAGES OF GEOFOAM

¡ Super

lightweight material

¡ Most

versatile lightweight materials available.

¡ Low density/ high strength: Geofoam

is 1% to 2 % the density of soil with equal strength.

¡ Predictable

behavior: Geofoam allows engineers to be much more specific in the design

criteria. This is very different than other lightweight fillers, such as soil,

that can be very variable in composition.

¡ Inert:

Geofoam will not breakdown, so it will not spread into surrounding soils, no leachates.

¡ Reused:

Geofoam can also be dug up and reused.

¡ Limited

labor required for construction: Geofoam can be installed by hand using simple

hand tools. This eliminates the investment and operating cost of heavy

machinery.

¡ Cuts

down on construction time: Geofoam is quick to install and can be installed

during any type of weather, day or night, resulting in faster installation

time. It can arrive at the job site prefabricated and ready to place and is

easily inventoried and handled.

¡ Installation

is not delayed by weather.

¡ It

maximizes onsite installation efficiency.

¡ Insect

and Mold Resistant

¡ Proven

Performance

¡ Maintenance

Free

¡ Contains

no CFC, HCFC, or HFC. Thus environment friendly.

DISADVANTAGES OF GEOFOAM

¡ Fire

hazards: Untreated Geofoam is a fire hazard.

¡ Vulnerable

to petroleum solvents: If Geofoam comes in contact with a petroleum

solvent, it will immediately turn into a glue-type substance, making it

unable to support any load.

¡ Buoyancy:

Forces developed because of buoyancy can

result in a dangerous uplift force.

¡ Susceptible

to insect damage: Geofoam should be treated to resist insect infestation. If it

is not, insects such as ants can burrow into the Geofoam, weakening the

material.

Present Scenario and Scope

¡ Has

been used around the world as a fill for more than 30 years.

¡ In

India, some industries manufacturing geotextiles also manufacture geofoam

blocks.

¡ However

use of geofoam is not seen on a large scale in India.

¡ Scope:

Soft soils in India are found near marine and river delta deposits.

Properties

• Density

• Compression

• Tension

• Creep

• Flexural

• Thermal Resistance

• Flammability

• Water Absorption

• Resistance to Attacks

• Durability

• Inertness Properties

• Energy Absorption

• Acoustical properties

• Environmental Effect

Density

¡ Can be considered to be the main index of its properties

¡ Cost of manufacture is considered proportional to density

¡ For practical civil applications it ranges between 11 and 30 kg/m3

Compression

Tension

¡ Tensile

strength of EPS material can be an indication of the quality of fusion of the

prepuffs and any recycled EPS geofoam used in the process.

¡ It

increases with density widely used as a quality control test in EPS geo-foam

manufacturing plants

Flexure

¡ Widely

used as a quality control test in EPS geo-foam manufacturing plants.

¡ The

maximum stress is calculated assuming the material is linear elastic up to

failure.

¡ The

material fails in tension as a crack on the tension side appears at the moment

of failure.

Creep

¡ Susceptible

to time dependent creep deformation when a constant stress level is applied

¡ Dependent

on

§

Density -- the creep decreases as density

increases

§

Stress -- lower the stress, lesser is the

creep deformation

Thermal Resistance and Flammability

¡ Poor

conductor of heat and therefore excellent for heat insulation

¡ Combustible

Water Absorption

¡ Low

¡ Depends

on:

§

Density

§

Fusion

Resistance to Attacks

¡ Sensitive

to attack by solvents

¡ Most

acids and their water solutions do not attack polystyrene; however strong

oxidizing acids do

¡ Does

not attack ants, termites, etc but is not resistant to them

¡ Not

susceptible to fungal attacks and bacterial growth

Environmental Effect

¡ EPS

geofoam is made of polystyrene beads and polystyrene is not biodegradable and

chemically inert in both soil and water

¡ Does

not contaminate the ground and ground water

¡ Recyclable

material

¡ Does

not use CFCs or HCFCs in its manufacture like other polymeric foam

¡ Good

energy absorber,

¡ Inert

and does not attack metals in contact with it,

¡ Reduces

transmission of airborne sound

Design and Construction Considerations

¡ Buoyancy

¡ Concentrated

Loads

¡ Chemical

Attack

¡ Flammability

¡ Insect

Infestation

¡ Moisture

Absorption

¡ Gaps

Between Blocks

¡ Immediate

Deformation

¡ Connections

with Structural and Architectural Elements

¡ Sliding

¡ Blocks

Alignment

¡ Transition

Zones

|

Lightweight

Material |

Unit Volume Weight (tf/m3)* |

Description |

|

EPS Blocks |

0.01 ~ 0.03 |

Ultra lightweight, expandable synthetic resins |

|

Expanded

Beads Mixed Lightweight Soil |

0.7 approx. or more |

Variable density; similar compaction and deformation characteristics

to soil; can use excess construction soil |

|

Air Foamed

Mortar and Air Foamed Lightweight Stabilized Soil |

0.5 approx. or more |

Density adjustable; flow able; self-hardening; and can use excess

construction soil |

|

Coal Ash,

Granulated Slag, etc |

1.0 ~ 1.5 ap-prox. |

Granular material; self hardening |

|

Volcanic Ash

Soil |

1.2 ~ 1.5 |

Natural material |

|

Hollow

Structures |

1.0 approx. |

Corrugated pipes, box culverts, etc. |

|

Wood Chips |

0.7~ 1.0 |

Usually to be used below ground water level; anti leaching measures

needed |

|

Shells |

1.1 approx. |

Sized 12 to 76 mm; interlocking effects |

|

Tire Chips |

0.7~ 0.9 |

Usually used above ground water level; cover soil layer at least 0.9m

is required |

METHODS OF CONSTRUCTION

¡ Done

in reference with ASTM D7180

¡ SUBGRADE

PREPARATION:

1. Clear and grub

site.

2. Excavate existing soil if required.

3. At design engineer’s discretion, place geotextile over

graded surface, i.e. soft

soils, etc.

4. Dewater site as required.

5. Place a sand pad/leveling course over the prepared

surface of 50 mm thickness minimum. Sand pad surfaces should be above ground

water level at time of EPS Geofoam

placement.

¡ PLACEMENT:

1. Verify identification marks on face of the product.

Field sampling and testing of the Foam-Control EPS Geofoam will be as specified

by the Engineer. Properties of density and compressive resistance shall be

verified in accordance with the specification.

2. Material is placed as required by the engineer and as

shown on the drawings.

3. Blocks of Foam-Control EPS Geofoam should be placed

tightly on the prepared sand pad/leveling course. For multiple layers of Foam-Control

EPS Geofoam, successive layers of blocks are oriented at 90 degrees to previous

layer.

4. Geofoam must

receive temporary ballast during all phases of construction to prevent

displacement by wind or high water conditions.

5. In order to

facilitate construction during precipitation or when frost or icing is

encountered, horizontal restraint (Geogripper) between layers of EPS Geofoam

may be desired.

6. Commence with

the placement of permanent overlying materials as quickly as practical.

¡ Geogripper:

Plates used to restrain EPS Geofoam from moving laterally in layer over layer

applications. The plate shall be made of galvanized or stainless steel with

two-sided multi-barbed design capable of piercing geofoam. Each plate shall be

capable of a lateral holding strength of 60 lbs (approx 27 kgs)

0 Comments

If you have any doubts, suggestions , corrections etc. let me know